Working with Stained Glass is an art; Creating the glass itself is a passion

For me a stained glass window is a transparent partition between my heart and the heart of the world. Stained glass has to be serious and passionate. -Marc Chagall

Marc Chagall, Stained glass windows, completed 1974, Reims Cathedral, Reims, France.

Misty, Bones and I arrived at Spectrum Glass in Woodinville just in time to join the last tour of the day. I left Bones in the pickup with side windows rolled down enough for air ventilation. This time I made sure the sliders in the back were locked. Before entering the building, I watched Bones for a few minutes to make sure he didn’t know how to unlock the sliders. He settled in the driver’s seat and seemed content to watch the surroundings.

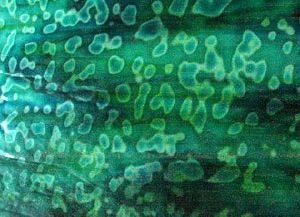

Glass production took place in a huge warehouse. We heard the sound of glass breaking as we entered. The guide showed us the raw materials used to make glass, primarily silica sand, soda ash and limestone. Adding different metal oxides creates the vibrant colors: copper for ruby glass, cobalt for blue, magnesium for purple, iron for green, uranium and cadmium for yellow, gold for pink.

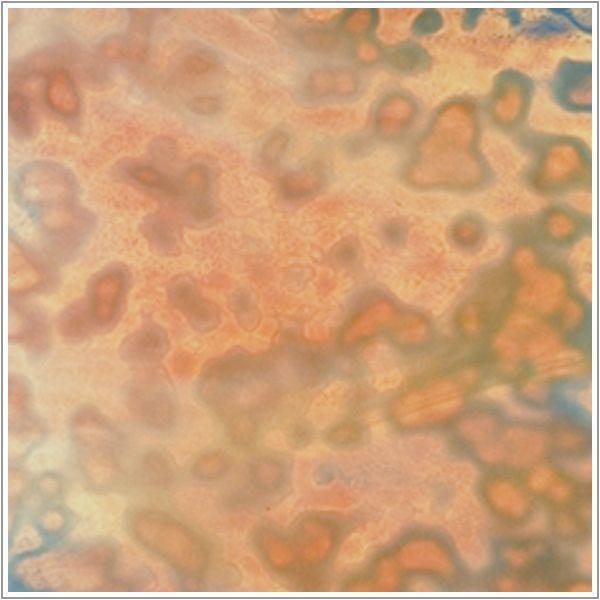

The raw materials are melted in a high-temperature furnace, at 2200 degrees Fahrenheit. We were taken to a viewing area to watch a man standing by a deep vat of molten glass. He was stirring the glass with a long pole. It takes a skilled person with artistic intuition to know how to stir the glass to make certain patterns. We were told each person who does this has their own unique technique and pattern signature.

During the melting state, metal oxides and pigments are applied to the surface. The molten glass is poured onto long tables through a process called rolling. This process determines the thickness and quality of the glass sheets. Freshly formed glass sheets go through an annealing process where they are slowly cooled in a temperature-controlled environment to prevent warping or cracking due to rapid temperature changes. Each sheet is inspected for imperfections, color consistency and structural integrity. Any deviations are removed and some are sold as one-of-a-kind pieces in the outlet store.

As the hot glass cools it forms edges that are not straight. We watched as workers cut the edges off to form rectangular sheets. The scraps were thrown into containers, which explained the sound of breaking glass we heard as we came in. Cutting the glass requires precision. The typical sheet size is 24” x 48” but each manufacturer can vary. Some sell sheets ranging from 16x32” to 32x42”.

After the tour, we went to the outlet store where we could buy glass. The discontinued glass and patterns that had been rejected for future sale were highly discounted. It was the perfect way for a beginning glass artist. Stained glass can cost anywhere from $18 to $52 sq. ft. and up, depending on color, texture, etc.

I have not worked with stained glass for several years, but recently found this press release that Spectrum Glass was closing:

Woodinville, Wash. – In a move that shocked many in the art glass world, Spectrum Glass has announced that they are going out of business. Spectrum, which makes System 96 fusing glass and numerous varieties of stained glass, intends to continue making glass for roughly two more months, then sell off its inventory and exit the art glass business.

Craig Barker, CEO of Spectrum Glass Company, shared this statement on the closure:

“After serving the art and specialty glass industry for 40 years, it is with very heavy hearts that we have decided to close Spectrum Glass Company.

“The decision to close our doors has been extraordinarily difficult. We postponed it for as long as possible, and arrived at this conclusion only after immense consideration. However, due to several factors, it’s no longer financially feasible for Spectrum Glass to continue to operate.

“Additionally, the entire U.S. art glass industry is now being evaluated by the Environmental Protection Agency (EPA) with respect to potential new regulations. Long-standing interpretations of air quality regulations are being reevaluated, and if new regulations were applied to our facility, it would require substantial capital expenses. Spectrum Glass Company has operated well within existing environmental guidelines and has been the only stained glass manufacturer to employ baghouse technology on furnace exhaust. Still, we have already accrued extraordinary, unanticipated expenses since the start of the EPA evaluation and cannot withstand additional investments of an unknown scale for an already faltering business…”

On the upside, there are still many wonderful artglass manufacturers who have weathered the economic downturn. Bullseye Glass in Portland, Oregon is still manufacturing stained glass in sheets, as well as frit, stringers and glass for kiln use.

Here is the link to a video of the making of one of the largest installations of stained glass in the U.S. It is an incredible story where new techniques were incorporated to make this amazing piece. https://videos.bullseyeglass.com/videos/resurrection-the-transformation-from-tradition-with-tim-carey-and-ted-sawyer/

Kokomo Opalescent Glass in Kokomo, Indiana claims to be the oldest manufacturer of colored glass in North America. They have been manufacturing since 1888. They still use the same manufacturing process used over a century ago.

Paul Wissmach Glass Company has manufactured stained glass since 1903 in Paden City, WV. They use 13 fire brick furnaces fueled by natural gas.

Youghiogheny Opalescent Glass Company, Inc. (pronounced Yuckagainy) is another old and trusted producer of quality art glass.

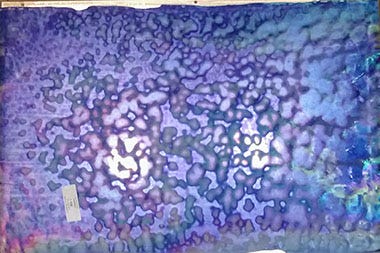

Oceana Cobalt Blue Iridized Glass by Youghiogheny (backlit)

Youghiogheny purchased Uroboros Glass from Oceanside Glass Tile in 2019. Youghiogheny is located in Connellsville, PA. Uroboros Glass was founded by Eric Lovell in 1973 and produced ring mottle glass, which was originally invented by the Tiffany Studios. The process was lost when Tiffany Studios closed in 1928, but claimed to have been rediscovered by Lovell. Uroboros was based in Portland, OR, but sold to Oceanside Glass & Tile in Carlsbad, CA in 2017. Oceanside discovered cadmium pollution near its site and moved production to Tijuana, Mexico.

Very interesting.

We put the stained glass butterfly you gave us in the window of our apartment here at

Stevenson Oaks.